Finishing

After all the parts are joined, glued and clamped, I’ll prep the surface to get ready for the finishing stage. Finishing is the point where the wood really comes to life and takes on a three dimensionality that has to be seen up close and touched to fully experience. I hand pad multiple coats of shellac to give the wood dimensionality and seal the grain before adding a topcoat of oil and varnish for luster and protection. Finally, I'll finish everything off with a coat of paste wax.

Fitting & Assembly

Once all the joinery is cut I'll begin to clean up and fit all the parts. This means trimming tenon shoulders to precisely fit into their corresponding mortises and paring dovetail walls for a friction-free fit. I'll then dry-fit all of the parts together to assess their relationship to each other and to find out if there will be an issues upon the final glue-up.

Surface prep and finishing

At this stage all machine, layout, and tool marks are cleaned off the wood through the use of hand planes, card scraper, and sandpaper. Any minor blemishes are attended to and interior surfaces are pre-finished with a washcoat of shellac.

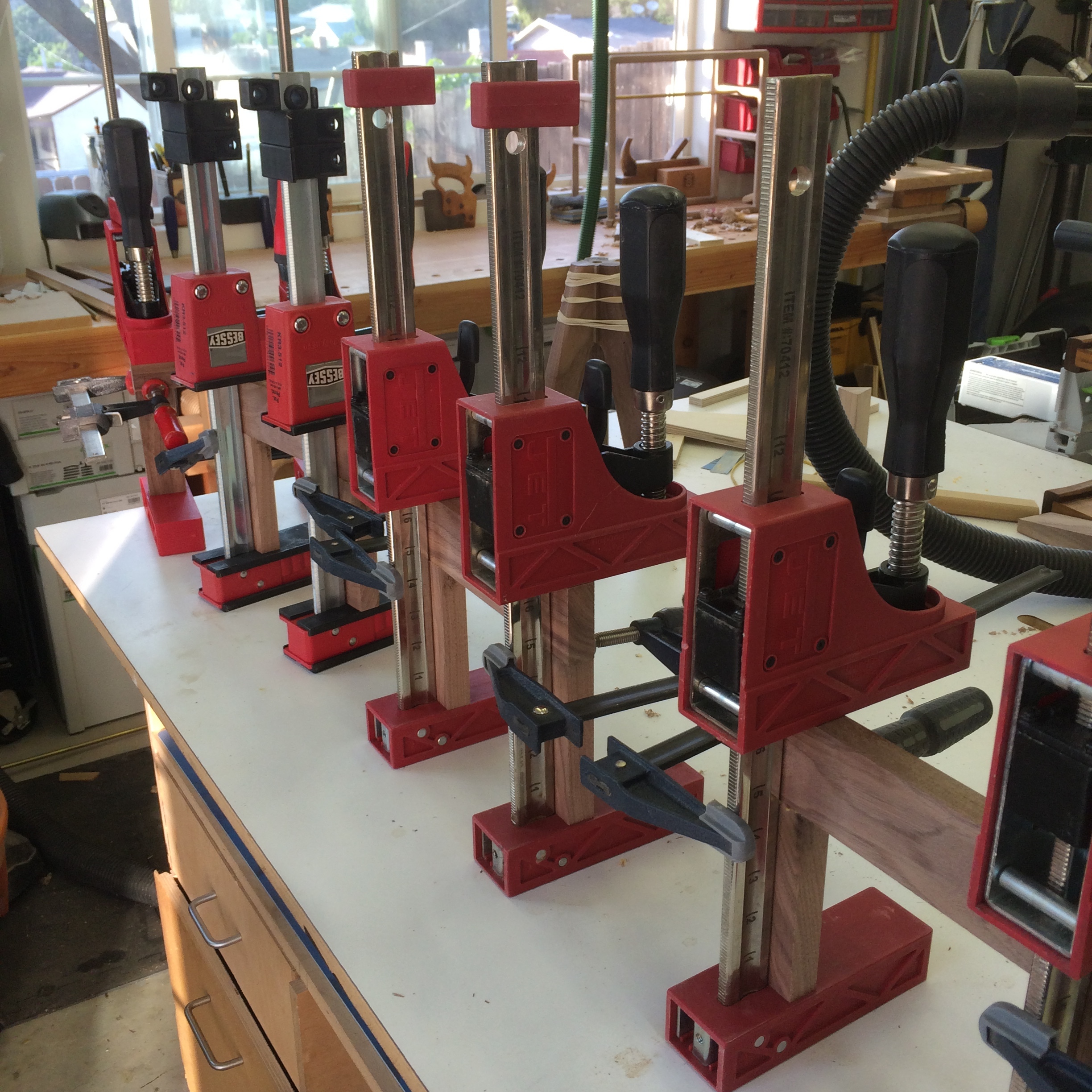

Glue up

Once your piece has been surfaced prepped, I'll begin the glue-up and final assembly of your piece. Clamps ensure that pressure goes where it's needed and the addition of yellow and protein hide glues to sound mechanical joinery ensures your piece will last a lifetime.

final finish

After all the parts are joined, glued and clamped, I’ll prep the outer surface to get ready for the finishing stage. Finishing is the point where the wood really comes to life and takes on a three dimensionality that has to be seen up close and touched to fully experience. I pad multiple coats of shellac to give the wood dimensionality before adding a topcoat of oil and varnish for luster and protection. A topper of paste wax seals the deal.